-

Model 2860: Class 1 Div 2 Rig Floor Computer: 19”

The 28xx-Series Zone 2 Touchscreen Computers are designed for rugged applications, including Measurement While Drilling, Electronic Drilling Recording, Depth Tracking, and all types of vehicle mounted applications. The series is available in 10.4”, 15”, and 19” sunlight readable displays. Each unit has room for customer-specific data acquisition boards to be installed and possibly certified for Zone 2 use. An innovative thermal design guarantees adequate cooling and reliable operation in all conditions including -40°C to +60°C temperatures, even when equipped with a high performance i7 CPU for the most demanding applications. Multiple I/O and wireless connectivity come standard. This Series is ideal for high performance computing in extreme environments.

-

Model 2900: Class 1 Div 1 Rig Floor Computer

This product is obsolete please check the newer version of the product.

-

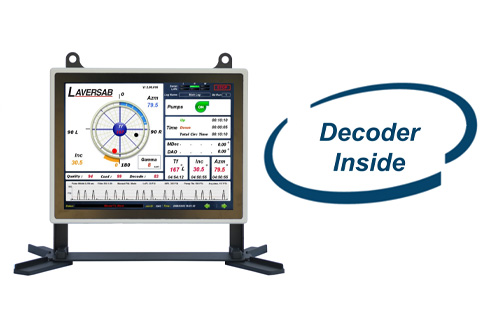

MWD Surface System: Decoder included

Laversab Models 4104 / 4152 / 4160 are Zone-2 certified surface systems capable of Positive-Pulse decoding at the driller’s cabin. The unit comes standard with an XXT decoder. Information is decoded and transmitted wirelessly to the safe area, removing the need for bulky cabling.

The system includes a Tool Programming Interface and complete software suite featuring Tool Config, Roll Test, Vibration Monitor and more to setup and program the downhole tool and surface receiver.

Over 1500 units of the Laversab 4100 family have been deployed. It is a seasoned and reliable tool for any directional drilling company.

-

MWD Surface System: Integrate Your Decoder

MWD Tool Designers can integrate their Decoders into Laversab Zone-2 units to create a certified MWD Surface System. These surface systems can decode and display data in any environment and wirelessly transmit information to the safe area. Systems can be configured to meet any rig requirement, and high performance CPU options are available.

Surface Systems designed with Laversab are certified for Hazardous Locations, more efficient to rig-up, and come with Laversab’s world-class service and renowned support. When quality matters, use Laversab.

-

MWD Surface System: Model 4100 (Legacy)

Laversab Model 4100 is a Class 1 Division 2 surface system designed for Legacy systems. The unit comes with an XXT decoder and software suite and is capable of decoding, displaying, and wirelessly transmitting downhole data.

The system includes a Tool Programing Interface to setup and program the downhole tool before a job.

For new requirements, Laversab recommends the Models 4104/4152/4160.

-

MWD Surface System: Zone 1 Display

Laversab Model 3200 is a Zone-1 certified Driller’s Display Unit (DDU). This ultra-compact unit is fully sealed and ready to be used on the rig. It typically pairs with a Decoder that resides in the safe area.

The Model 3200 displays critical MWD telemetry information including ToolFace, Inclination, Azimuth and more; the 3200 can also be customized to display WITS0 data. The ATEX/IECEx Zone 1 certifications make this unit suitable for both Offshore and Onshore deployment.

-

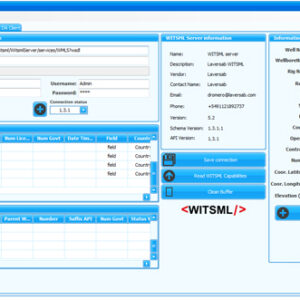

PLC Connector to WITSML™

The Laversab PLC Connector converts PLC well data to WITSML formats. The PLC Connector enables equipment data to be analyzed with drilling data. Operators and service companies can derive insights on rig equipment performance correlates to drilling performance. They can also monitor equipment to predict and prevent failures.

PLC Connector supports Modbus TCP/IP, OPC, SLC 500 (Rockwell/Allen Bradley), Step 7 (Siemens), and other protocols.

Data across multiple rigs and fields can be compared and analyzed to provide insights into true overall performance. Custom analysis and reports are available from Laversab.

-

Real-time Server: WITSML™ Store

Laversab WITSML™ Store is a cloud-based server built to handle data coming from multiple rigs. It is responsible for securely managing all drilling parameters. WITSML™ Store is accessible by authorized users 24/7/365.

Drilling data can be transmitted to WITSML™ Store directly from the rig-site. And it is instantly available for any authorized users.

WITSML™ Store is compatible with WITSML™ versions 1.3.1 and 1.4.1. It can be customized to meet specific customer requirements. And can be installed on a local server instead of the cloud.

-

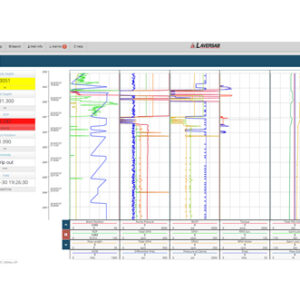

Real-time WITSML™ Client: WellNode

Laversab WellNode is a Real-Time Client for visualizing and analyzing well data. It is used by clients and decision makers away from the rig to monitor progress and provide direction. WellNode provides both time-based and depth-based information and analysis across multiple wells. WellNode is suitable across any type of drilling job.

WellNode Modules include 3D trajectory, Well Planning, Lithology, KPI analysis, among others.

WellNode is compatible with WITSML™ versions 1.3.1 and 1.4.1. It can be customized to meet specific customer requirements.

-

Rig Monitoring Solutions

Laversab software can monitor the performance of critical rig equipment – including engines, pumps, and others. Key Performance Indicators (KPIs) are used to measure and predict failures, downtime, and maintenance work. The Laversab platform can set custom alerts and calculate MTBF, MTTR, and DMECA. Monitoring can be done across multiple wells to compare an entire field.

-

Stand-alone Depth Tracker: Model 2854-DT

The Laversab Model 2854DT is a stand-alone depth tracker, capable of recording depth data while drilling. The stand-alone depth tracker is certified for use in Zone 2 hazardous locations. It includes easy-to-use software for sensor calibration and data recording. Existing encoder and hook-load sensors/cables can be used, or new ones can be provided. Relevant application range from simple depth collection to advanced data logging and reporting.

Depth data is formatted as WITS0 and/or WITSML™. It can be stored locally or used by any external applications. If no EDR is available, the stand-alone Depth Tracker can be the primary depth logger.

-

Stand-alone Depth Tracker: Model 4210 (Legacy)

The Laversab Model 4210 is a stand-alone depth tracker, capable of recording depth data while drilling. The stand-alone depth tracker is certified for use in Zone 2 hazardous locations. It includes easy-to-use software for sensor calibration and data recording. Existing encoder and hook-load sensors/cables can be used, or new ones can be provided. Relevant application range from simple depth collection to advanced data logging and reporting.

Depth data is formatted as WITS0 and/or WITSML™. It can be stored locally or used by any external applications. If no EDR is available, the stand-alone Depth Tracker can be the primary depth logger.

- Home

- About

Products

Avionics Radio Test Sets

Air Data Test Sets

- Product Selector

- Quote Request

- Customer Support

- Contact