NON-CERTIFIED HEADLESS SYSTEM MODEL 2100

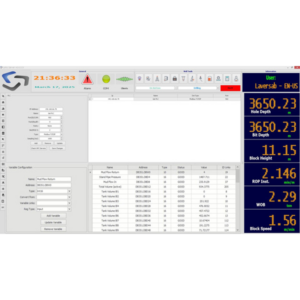

Non-certified Headless System to collect rig system data and convert to WITSMLTM.

Target Application: Remote environments, Interface with existing systems

Description: Laversab Model 2100 is a non-certified ultra-compact headless system. It is designed to interface with other rig systems to pull data from PLCs and other networks and then publish data to a WITSMLTMserver.

The Model 2100 can be customized to fit exact channel requirements, certification levels, and performance. Several data sources or protocols are supported – WITS0, WITSMLTM, Modbus RTU, Modbus TCP, OPC, Siemens PLCs, Rockwell PLCs, Profibus, ASCII, SQL, MySQL

| Test Set Type | Air Data Ramp |

|---|---|

| Aircraft Type | Business Jet, Commercial, Helicopter, GA, & Non-RVSM |

| RVSM Capable | Yes |

| Max Aircraft Altitude | 50,000 ft, 60,000 ft |

| Max Aircraft Airspeed | 500 knots, 600 knots, 650 knots, 690 knots |

| Number of Channels | 2 |

| Target Application | Business Jet & Commercial |

| Range | -2,000 to 60,000 ft |

| Resolution | 1 foot |

| Accuracy | 2 ft. @ 0 ft. 3 ft. @ 10,000 ft. 4 ft. @ 20,000 ft. 6 ft. @ 35,000 ft. 12 ft. @ 50,000 ft. |

| Rate | 0 to 500 knots/min |

| Remote controller | Standard |

| Wi-Fi | Standard, Yes |

| RS-232 interface | Standard |

| IEEE-488 interface | Not Available |

| Encoder input | Optional |

| 28 VDC Power | Not Available |

| Battery | Optional, Yes |

| Heaters | Optional |

| Warranty | 3 Years |

| Displayed Static Units | feet, meters, inHg, mbar, psi, mmHg, kg/cm2 |

| Displayed Pitot Units | knots, Mach, kmph, mph, inHg, mbar, psi, mmHg, kg/cm2, EPR |

| Power Requirement | 90-260 VAC, 47-400 Hz, 100 W (200W with Heaters) |

| Dimensions & Weights | 22" x 14" x 9" / 34 lbs. |

| Calibration Interval | Annual |

| Operating Temp. | 0°C to 50°C |

| Optional Temp Ranges | -40° C to 50°C |

| Humidity (non-condensing) | 5 to 100% |

| Altitude capability (ft) | 50,000 ft, 60,000 ft |

| Airspeed capability (knots) | 500 knots, 690 knots |

| Wide Temp capable | Yes |

| Battery/Wi-Fi capable | Yes |

| Capability | Battery/Wi-Fi, RVSM Capable, Wide Temp |

| Range socf | 0 to 15,000 ft./min |

| Accuracy socf | 1% of Rate |

| Resolution socf | 1 ft./min |

| Range poaf | 0 to 690 knots |

| Rate poaf | 0 to 500 knots/min |

| Resolution poaf | 0.1 knot |

| Accuracy poaf | 0.04 knots @ 500 knots, 0.1 knots @ 200 knots, 0.2 knots @ 100 knots, 0.3 knots @ 50 knots, 1.0 knots @ 20 knots |

| comparison_order | 2 |

You may also like…

-

WITS0 to WITSMLTMCONVERTOR LINKS COLLECTOR

Read moreConvert all drilling data to WITSMLTM.

Target Application: Land rigs, Offshore rigs, Work-over rigs

Description: Laversab LINKS Collector can convert all drilling data to WITSMLTM.

WITSMLTMversions 1.3.1 & 1.4.1 are currently supported.

LINKS Collector can handle most data formats – from WITS0 to proprietary formats used by equipment companies. LINKS Collector is a low-footprint software that can run on any rig system. It can also act as a data aggregator by correlating data from multiple rig sources.

-

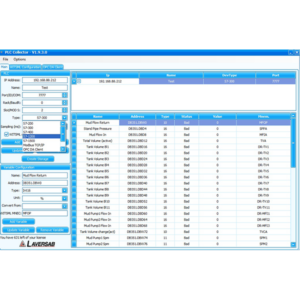

PLC to WITSMLTMCONVERTOR PLC COLLECTOR

Read moreConvert PLC data to WITSMLTM

Target Application: Any Drilling or Production rig

Description: Laversab PLC Collector converts PLC data to WITSMLTMThe PLC Collector enables equipment data to be analyzed together with drilling data. Operators and service companies can uncover insights on how rig equipment performance correlates to drilling performance. They can also monitor equipment to predict and prevent failures.

PLC Collector supports Modbus TCP/IP, OPC, SLC 500 (Rockwell/Allen Bradley), Step 7 (Siemens), and other protocols.

Data across multiple rigs and fields can be compared and analyzed to provide insights into actual rig performance. Custom analysis and reports are available from Laversab.

-

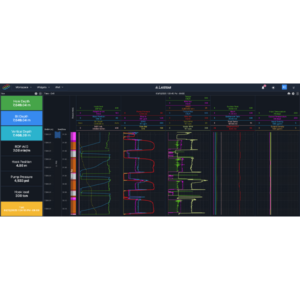

WITSMLTM DATA ANALYZER WellNode

Read moreWITSMLTMdata analyzer with dashboard visualization for RTOCs.

Target Application: Real-time Operating Center, Remote monitoring

Description: Wellnode is a dashboard-based visualization and analysis application built to monitor one or multiple wells in real-time. It supports WITSMLTMand ETPTM data coming from any source – EDR, Mudlogging unit, Directional Drilling, Managed Pressure Drilling, Logging while Drilling, among other. Users can create dynamic dashboards in a Real-time Operating Center (RTOC) to closely manage their wells, gain insights, and create reports.

Capabilities include:

- Real-Time WITSMLTMdata visualization

- Support for WITSMLTMv 1.3.1.1 & 1.4.1.1

- Customizable dashboards

- Key Performance Indicators (KPIs) dashboard

- Alarms Module

- Time & Depth-based exportable reports

- Wellbore visualization

- Operational Limits

- Lithology

- Engineering Analysis

- Predictions