Headless Systems

Laversab systems are certified for hazardous zones, including Zone 1, Zone 2, and Class 1 Division 2. They simplify MWD decoder integration, allowing manufacturers to avoid lengthy certification processes. These advanced surface systems feature wireless connectivity, a 3-year warranty, and are available directly from Laversab or its trusted partners.

THE LAVERSAB ADVANTAGE

Reliability

Quality equipment with a 3-year warranty

Performance

Leading technology & capability

Adaptable Solutions

Designed to fit any requirement

Quick Setup

Designed to start job immediately

Service

24/7 support & available training

Experience

40+ years of delivering solutions

THE LAVERSAB ADVANTAGE

Reliability

Quality equipment with a 3-year warranty

Performance

Leading technology & capability

Adaptable Solutions

Designed to fit any requirement

Quick Setup

Designed to start job immediately

Service

24/7 support & available training

Experience

40+ years of delivering solutions

SYSTEM COMPONENTS

WHY CHOOSE LAVERSAB HEADLESS SYSTEMS?

SOLUTIONS

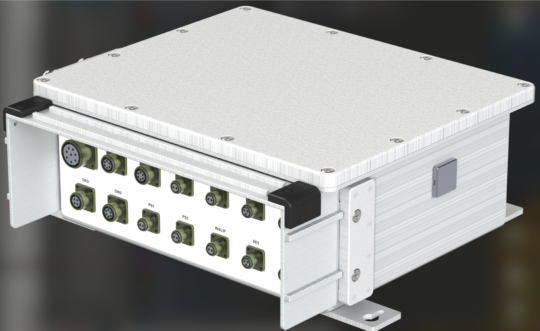

ZONE 1 – Logging & Measurement While Drilling Embedded System

Laversab has designed a Zone-1 embedded system for use on offshore drilling rigs. It can collect both high-speed data from pressure transmitters and low-speed surface data from the encoder, hookload, pump strokes, and slips.

The system can transmit Modbus data to a central server over fiber or ethernet, and it can be daisy-chained for high channel requirements.

Non-certified – Model 2100

The Model 2100 is a non-certified system designed for

controlled environments on oil platforms. It can interface

directly with existing data collection systems over OPC & Modbus. The 2100 coverts the data and transmits over

WITSMLTM to a centralized server.