Data acquisition system for drilling rigs. Real-time surface paramaters.

Target Application: Work-over rigs, Land rigs, Offshore drilling rigs

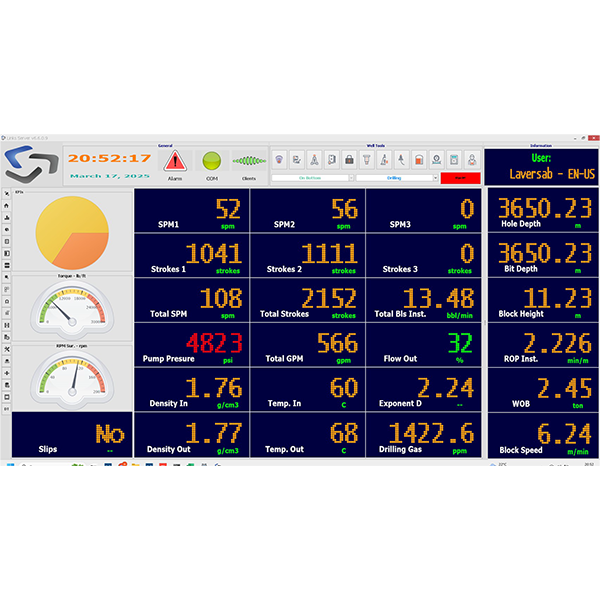

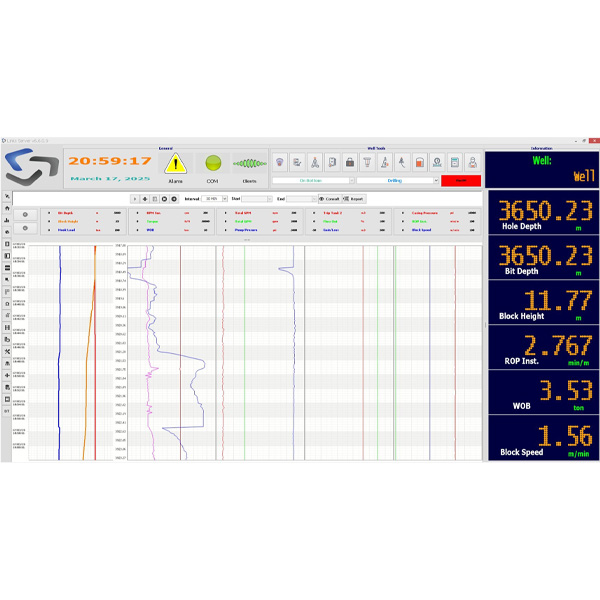

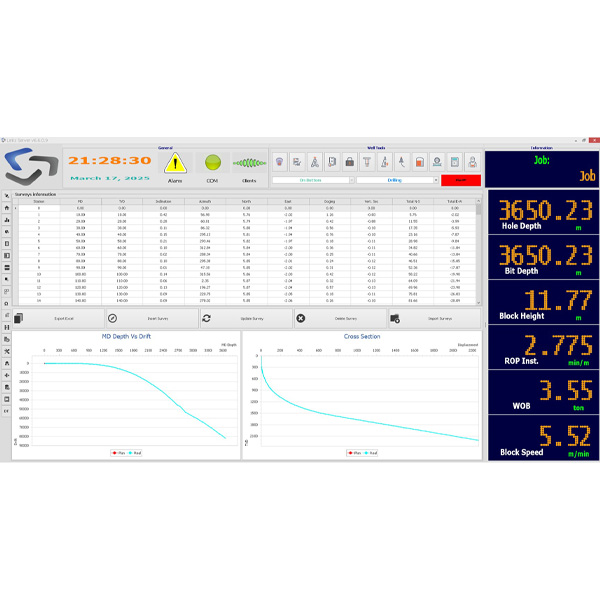

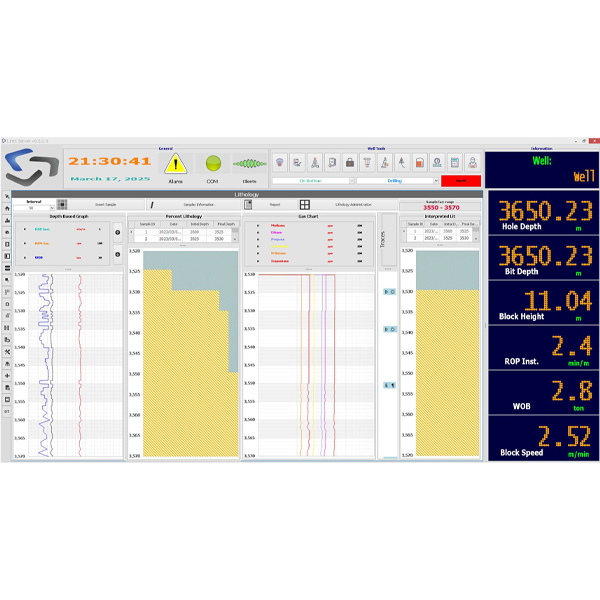

Description: The Laversab EDR is a data acquisition system with purpose-built software to monitor surface parameters in real-time. It designed for multiple applications on the drilling rig, including Depth Logging, Mudlogging, Lithology, Pit Volume Totalizer (PVT), and more.

The EDR makes real-time surface parameters available to the driller, operator, and offsite stakeholders. Key Performance Indicators, Tour Sheets, and Daily Reports are generated by the LINKS EDR Software. The system works with typical surface measurement sensors, which can be reused across multiple jobs.

Customers can select the number of channels, junction boxes (JBs), sensors, and cables they require for each system. Rigs with existing sensors and hardware can be updated to use the Laversab EDR. This system is highly portable and can be relocated after a job is completed.