Measurement While Drilling (MWD)

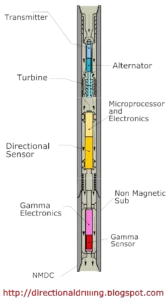

A Measurement While Drilling (MWD) system is a sophisticated setup used to gather real-time data from the bottom of the wellbore during drilling operations. Here are the key elements:

Sensors:

-

-

- These include accelerometers and magnetometers that measure the wellbore’s inclination and azimuth. Additional sensors can measure parameters like temperature, pressure, and gamma radiation.

-

Telemetry System:

- This system transmits data from the downhole sensors to the surface. Common methods include mud pulse telemetry, which sends pressure pulses through the drilling mud, and electromagnetic telemetry.

Downhole Tools:

- These tools house the sensors and telemetry equipment. They are typically placed in a non-magnetic drill collar to avoid interference with the measurements.

Surface System:

- This includes the equipment and software used to decode the transmitted data and present it to the drilling operators. It often features displays and interfaces for real-time monitoring and analysis.

Power Supply:

- Downhole tools require a reliable power source, which is usually provided by batteries or turbine generators driven by the flow of drilling mud.

Data Processing Unit:

- This unit processes the raw data collected by the sensors, converting it into useful information that can be used to make decisions about the drilling process

These components work together to provide continuous, real-time data that helps in steering the drill bit, optimizing drilling performance, and ensuring the safety and efficiency of the drilling operation.