Depth Tracking

A Depth Tracker on a drilling rig is crucial for accurately measuring and monitoring the depth of the drill bit. Here are the main components:

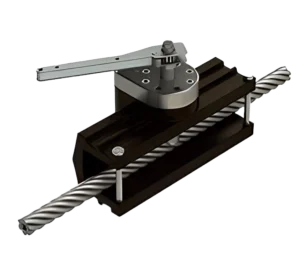

Encoder:

-

-

- This device measures the rotation of the drawworks drum, which is used to calculate the depth of the drill bit. It converts mechanical motion into electrical signals that can be processed by the system.

-

Hook Load Sensor:

- This sensor measures the weight on the hook, which helps in determining the weight on the bit (WOB) and other critical parameters. It ensures accurate depth tracking by accounting for the load on the drilling line.

Slip Switch:

- This switch detects when the slips are engaged or disengaged. It helps in identifying when the drill string is stationary or moving, which is essential for accurate depth measurement.

Data Acquisition Unit (DAU):

- This unit collects data from the encoder, hook load sensor, and slip switch. It processes and transmits the data to the surface system for real-time monitoring and analysis.

Surface System:

- This includes the hardware and software used to display and analyze the depth data. It often features user-friendly interfaces for operators to monitor the drilling process.

Power Supply:

- A reliable power source is necessary to ensure continuous operation of the depth tracking system. This can be provided by batteries or direct power from the rig.

These components work together to provide accurate and real-time depth measurements, which are critical for efficient and safe drilling operations.