Electronic Drilling Recorder

The Laversab EDR is a complete solution for collecting, analyzing, and storing drilling data. It includes LINKS software, a data acquisition system, cables, and sensors. Its modular, scalable design works with new or existing setups, supporting applications like Mudlogging and PVT.

THE LAVERSAB ADVANTAGE

Reliability

Quality equipment with a 3-year warranty

Performance

Leading technology & capability

Adaptable Solutions

Designed to fit any requirement

Quick Setup

Designed to start job immediately

Service

24/7 support & available training

Experience

40+ years of delivering solutions

THE LAVERSAB ADVANTAGE

Reliability

Quality equipment with a 3-year warranty

Performance

Leading technology & capability

Adaptable Solutions

Designed to fit any requirement

Quick Setup

Designed to start job immediately

Service

24/7 support & available training

Experience

40+ years of delivering solutions

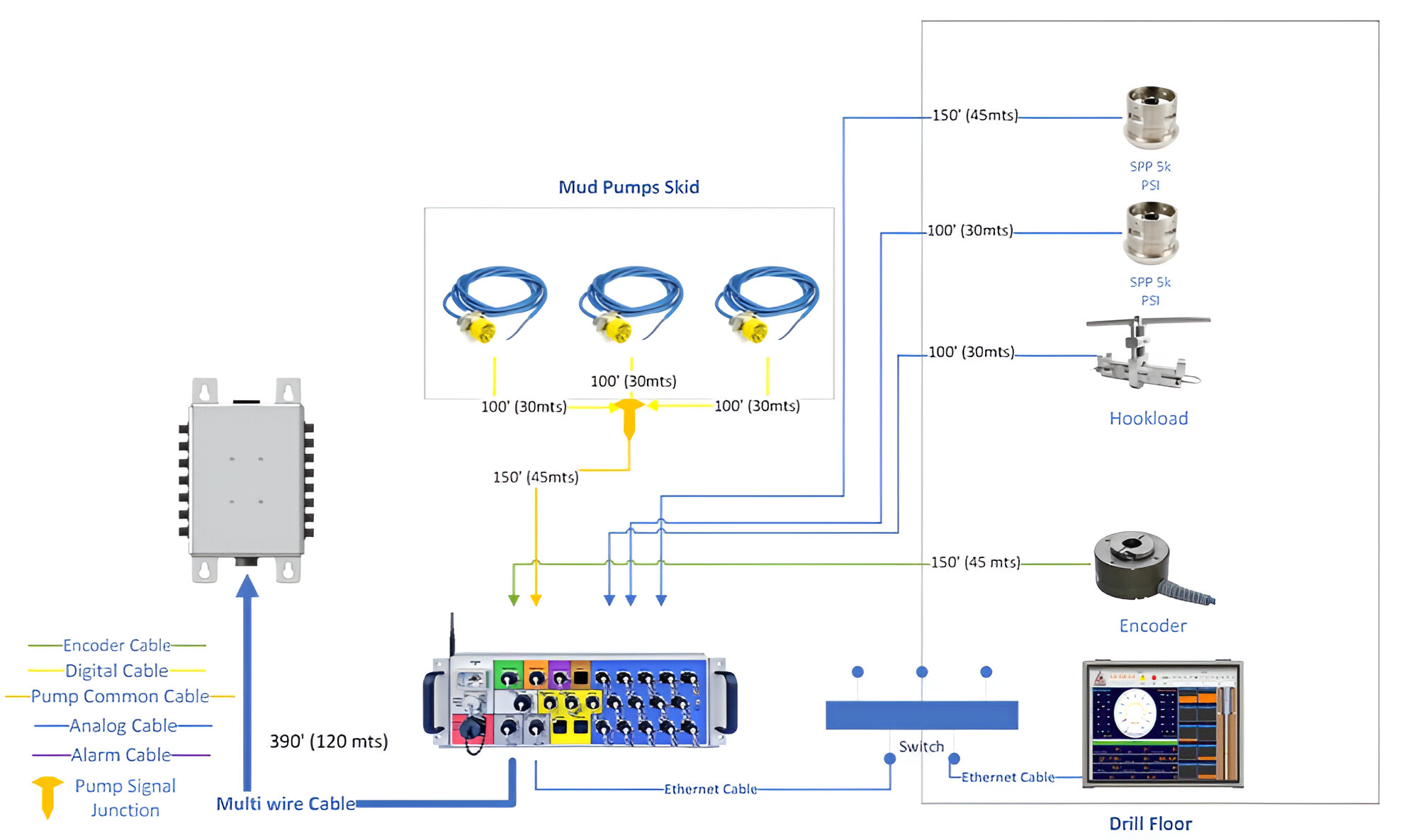

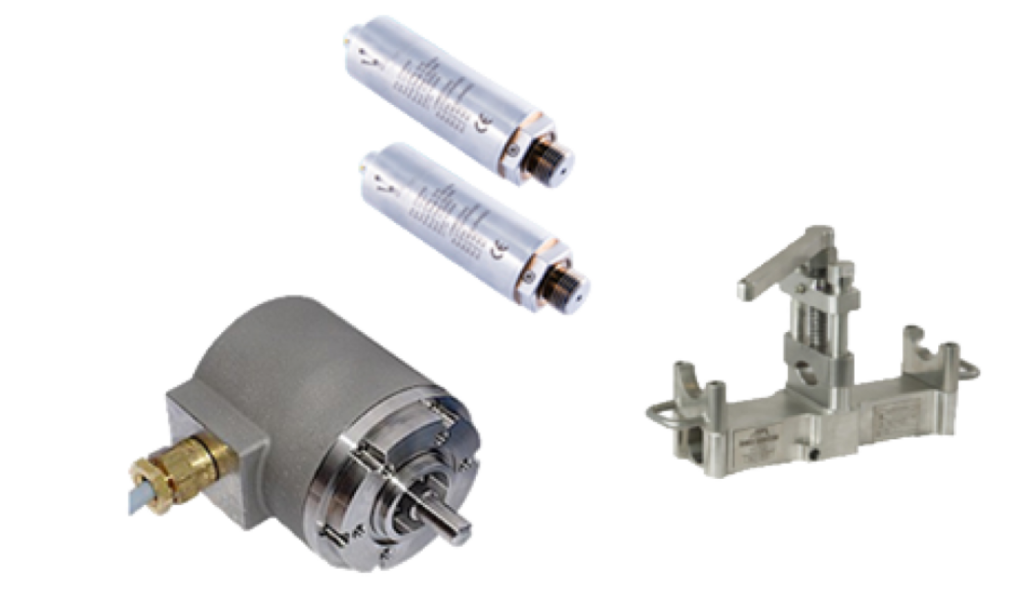

SYSTEM COMPONENTS

Channels

The Laversab EDR can be configured by number of channels – Analog, Digital, Pumps, Encoder, WITS0 Input/output, Alarms

Software

Select capabilities from LINKS Software platform.

Options:

- LINKS Collector: Multi-source data collection and aquisition

- WITSMLTM Publisher

- Lithology Module

- Tour Sheet Modul

Sensors

Determine the sensors required for a given job or system. Existing sensors can be reused.

Cables

Choose cables to fit the distances required on the rig and interface with sensors. Select cable length and connector types accordingly.

Junction Box

For larger rigs or platforms, Junction Boxes (JBs) can be used to reduce the length of cables to far-away sensors. JBs are commonly used for the Pumps & Pits area.

WHY CHOOSE LAVERSAB EDRs?

SOLUTIONS

Multiple variations of solutions are possible. Below is a common example of a system that can be deployed across many rigs.